ALGI: Modernizing Elevators for Improved Performance and Safety

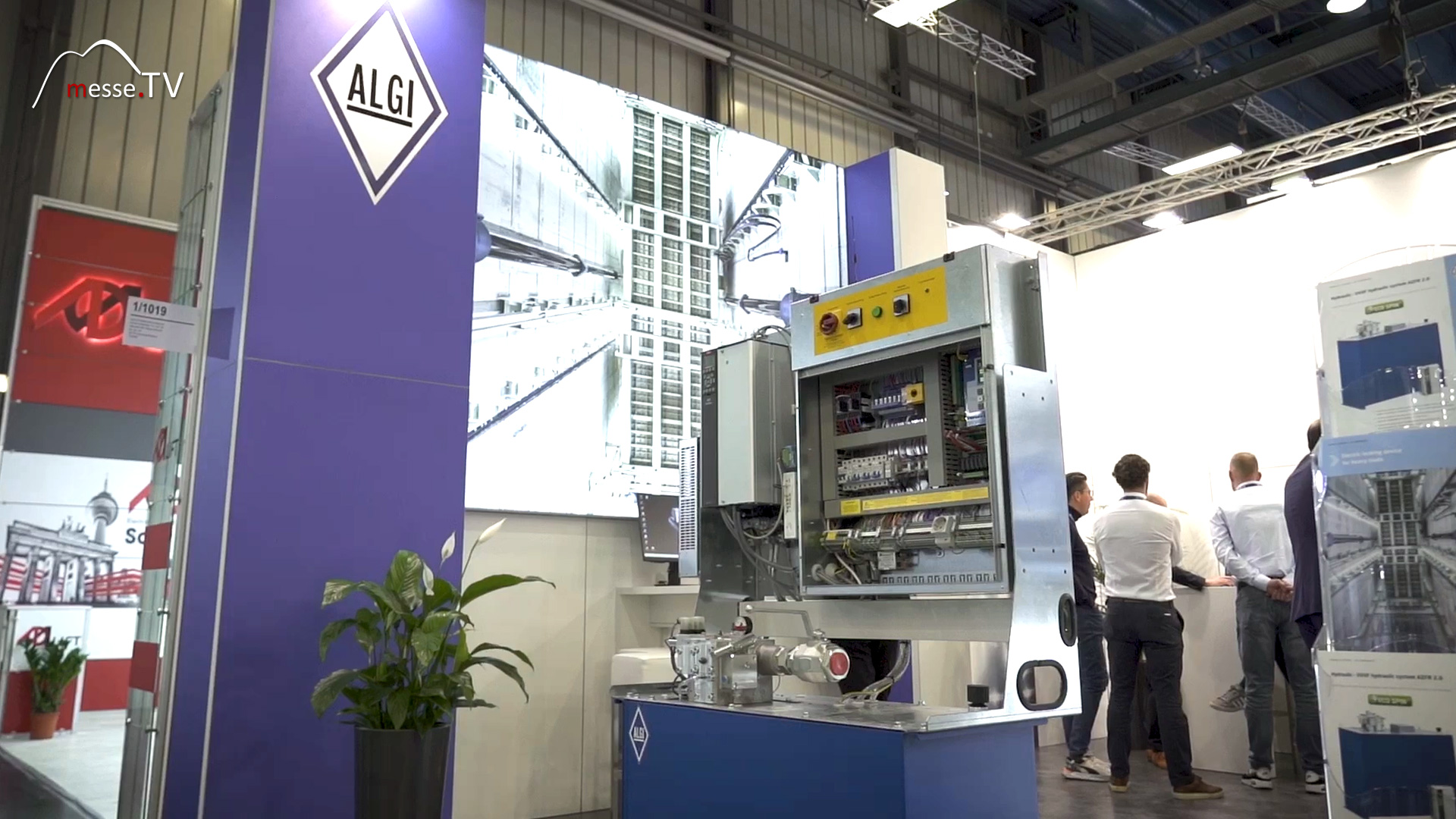

One of ALGI's highlights at interlift 2023 in Augsburg is the topic of modernization.

The Augsburg-based company ALGI has been active in the field of hydraulic drives for elevators since 1959. Managing Director Harald Giehl names modernization as one of the highlights of his company ALGI. There are more than 700,000 existing lifts in Germany. Together with the company New Lift, ALGI has therefore developed a frequency inverter, a control unit and a hydraulic power unit for modernization.

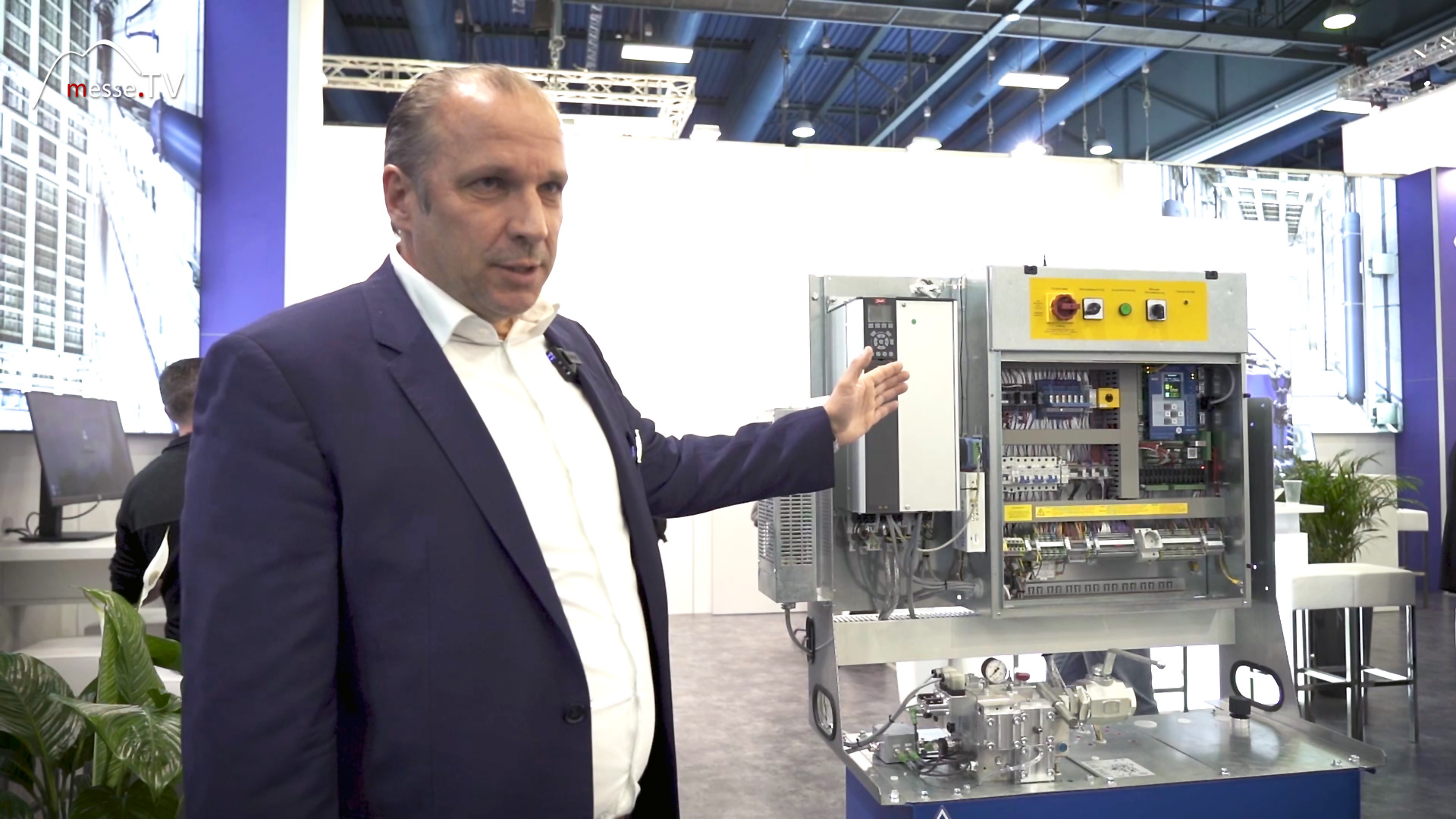

Modernization of elevator systems: energy-saving drives

The technical innovation is a control system that can be used to access the drive. In other words, a remote system that allows the elevator company to access the elevator system from anywhere in the world from the office. Values can be read out and settings made on the drives. A modern solution that is further optimized by energy-saving drives.

Frequency-controlled drive for greater energy efficiency

Drives play a particularly important role in the modernization of existing systems. Lifts, for example, can fulfill their function in the shaft for up to 90 years. When it comes to energy saving and energy efficiency, a frequency-controlled drive can help. A special concept developed jointly by NEW and ALGI ensures that the drive and control unit can be replaced within a few days during installation. Thanks to pre-assembly and pre-assembly of the control unit by the control unit manufacturer, the fitter only has to connect a few plug connectors between the drive and control unit on site. The rear panel can then be attached to the unit with just 4 screws. This means that the operator can be replaced with the control unit in no time at all. The time saving is particularly important for private and public facilities such as hospitals and hotels, where a long downtime of the elevator system would be fatal.